Types of Hydraulic Fittings and Their Applications

Hydraulic power drives the machines that build our cities, move our industries, and keep vital operations running. Behind this immense force lies a network of hydraulic fittings - small components with a big responsibility. They connect hoses, pipes, and tubes to create leak‑free, high‑pressure systems that must perform flawlessly under demanding conditions.

At Al Kun Steel, we understand that every project demands fittings that meet international standards and withstand demanding environments. This blog explores the different hydraulic fitting types and their applications, helping businesses make informed decisions when selecting components for their systems.

Understanding Hydraulic Fittings

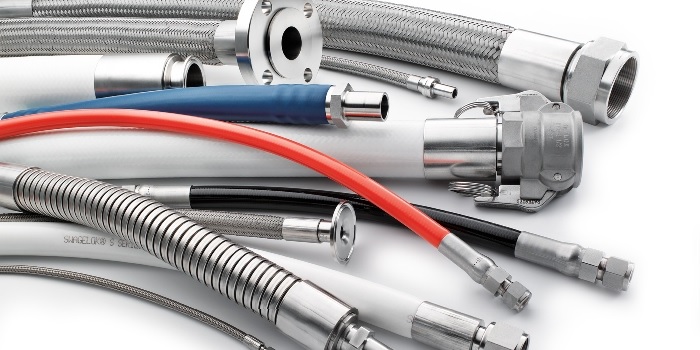

Hydraulic fittings are designed to connect various elements of a hydraulic system - hoses, pipes, and tubes - while maintaining a secure, pressure‑resistant seal. They ensure that hydraulic fluid flows smoothly without leaks, even under extreme operating conditions.

From hydraulic hose fittings that connect flexible hoses to rigid components, to hydraulic connector fittings that adapt different thread types or diameters, these parts are indispensable in keeping hydraulic systems efficient and safe.

Importance of Quality Hydraulic Fittings

The choice of fittings directly impacts the performance of hydraulic systems:

- Safety: High‑quality fittings are engineered to withstand high pressure, preventing leaks and bursts that could endanger workers and damage equipment. They create secure connections that keep hydraulic systems operating safely.

- Efficiency: Properly selected fittings maintain consistent fluid flow throughout the system. This reduces energy loss, minimizes downtime, and ensures machines perform at their peak capacity.

- Durability: Reliable fittings are built to resist corrosion, wear, and extreme temperatures. Their long service life reduces maintenance costs and ensures uninterrupted operations in demanding environments.

- Compliance: Certified fittings meet international standards for performance and safety. This guarantees reliability across industries and helps businesses maintain regulatory compliance.

Types of Hydraulic Fittings

There are several hydraulic fitting types, each serving a specific purpose in system design:

- Adapters: Adapters are used to connect different thread types or sizes, making them essential when integrating components from varied standards. They ensure compatibility across the system and prevent mismatched connections that could lead to leaks or inefficiencies.

Elbows: Elbows change the direction of fluid flow, typically at 45° or 90° angles. They are critical in systems where space constraints or design layouts require fluid to move around corners without disrupting pressure or flow consistency.

- Tees & Crosses: These fittings allow branching into multiple lines, distributing hydraulic fluid to different parts of the system. They are widely used in complex setups where multiple actuators or machines need to be powered simultaneously.

- Couplings & Unions: Couplings and unions provide secure connections between pipes or hoses while allowing easy disconnection for maintenance. They are especially valuable in systems that require frequent servicing or replacement of components.

- Reducers: Reducers connect pipes or hoses of varying diameters, ensuring smooth transitions without compromising pressure balance. They help maintain system efficiency when different equipment sizes are integrated into one hydraulic network.

- Flanges: Flanges offer strong, secure connections for heavy‑duty hydraulic systems. Commonly used in high‑pressure applications, they provide stability and durability, making them ideal for industrial environments where reliability is non‑negotiable.

- Valves: Valves control or regulate fluid flow, ensuring precision and safety in hydraulic operations. They allow operators to start, stop, or adjust flow rates, making them indispensable for maintaining system performance and protecting equipment.

Applications of Hydraulic Fittings

Hydraulic fittings are used across diverse industries:

- Construction Equipment: Excavators, loaders, and cranes rely on hydraulic hose fittings to deliver smooth, uninterrupted power. These fittings ensure heavy machinery operates efficiently under high‑pressure conditions on demanding job sites.

- Manufacturing Plants: Hydraulic presses, injection molding machines, and assembly lines depend on durable hydraulic pipe fittings. They maintain consistent fluid flow, supporting precision manufacturing and minimizing costly downtime.

- Oil & Gas Industry: Pipelines, rigs, and refineries use hydraulic connector fittings to withstand extreme pressures and corrosive environments. Their reliability is critical for safety and efficiency in high‑risk operations.

- Automotive Sector: Brake systems, power steering, and heavy vehicles require precision‑engineered fittings. These ensure hydraulic systems respond accurately, safeguarding performance and driver safety.

- Agriculture: Tractors, irrigation systems, and hydraulic pumps depend on fittings built to endure outdoor conditions. Strong, weather‑resistant fittings guarantee continuous operation across long working hours in the field.

How to Select the Right Hydraulic Fittings

Selecting the right fittings involves careful consideration:

- Pressure & Temperature Ratings: Fittings must be able to withstand the operating pressure and temperature of the system. Choosing the right rating ensures safety, prevents failures, and guarantees long‑term reliability.

- Material Selection: Options like steel, brass, or stainless steel should be chosen based on the fluid type and environment. The right material resists corrosion, wear, and ensures durability under demanding conditions.

- Compatibility: Fittings must match hoses, pipes, and connectors to create a secure, leak‑free system. Proper compatibility avoids inefficiencies, contamination, and costly maintenance issues.

- Supplier Credibility: Partnering with a trusted supplier ensures access to certified products and technical expertise. A reliable supplier provides quality assurance and helps businesses maintain compliance with industry standards.

Hydraulic Fittings Solutions by Al Kun Steel

As one of the leading hydraulic fittings suppliers in UAE, Al Kun Steel provides a wide range of hydraulic fittings, including metric hydraulic fittings and BSP hydraulic fittings. Our products are rigorously tested for durability, performance, and safety, ensuring they meet international standards and serve industries reliably across the region.

Whether your project involves construction equipment, oil pipelines, or manufacturing plants, Al Kun Steel delivers tailored solutions that prioritize quality and long‑term success. By choosing our hydraulic hose fittings and hydraulic pipe fittings, businesses safeguard their investments and enhance operational efficiency.

Conclusion

Hydraulic systems are complex networks where every component plays a role in overall performance, but fittings are the elements that hold everything together. When fittings lack strength or precision, the consequences can be serious - leaks, downtime, and safety risks. High‑quality fittings, on the other hand, provide secure connections, maintain fluid integrity, and ensure systems run efficiently across industries such as construction, manufacturing, oil & gas, automotive, and agriculture.

For businesses in the UAE, the choice of supplier is as important as the choice of fitting itself. Partnering with Al Kun Steel means access to a wide range of rigorously tested solutions, including hydraulic connector fittings, metric hydraulic fittings, and BSP hydraulic fittings that meet international standards. By investing in fittings that combine durability, compliance, and performance, companies can safeguard their operations, reduce maintenance costs, and build systems designed to last. In hydraulic applications, quality is the foundation of safety, efficiency, and long‑term success.

Related Articles

Stainless Steel Buttweld Fittings For Offshore Shipbuilding And Platform Piping

Read MoreIndustrial Valves, Hoses & Gaskets: Alkun Steel’s Solutions for the Tanks & Pumps Industry

Read MoreCorrosion-Resistant Valves, Flanges & Joints: Alkun Steel’s Petrochemical Solutions

Read MoreWhy Alkun Steel Is A Reliable Supplier Of Essential Products In The Oil Drilling & Rig Industry

Read MoreReliable Industrial Components For Fire Fighting Applications: Alkun Steel’s Trusted Solutions

Read MoreWhy Alkun Steel Is A Reliable Supplier Of Essential Products In The Fabrication Industry

Read MoreIndustrial Valves, Hoses & Gaskets: Alkun Steel’s Solutions For Aviation Maintenance

Read MoreBest Weld Neck, Slip-On, And Blind Flanges For Critical Oil & Gas Connections

Read MoreBest Industrial Fasteners for Heavy Equipment Assembly and Structural Steel Projects

Read More