Why Quality Pipe Fittings Matter in Industrial Projects

Pipe fittings may seem like small components in the grand scale of industrial projects, but they are fundamental to the integrity and efficiency of entire systems. From oil pipelines and water distribution networks to HVAC installations and chemical plants, fittings ensure that pipes connect securely, redirect flow when needed, and withstand the pressures of demanding environments.

At Al Kun Steel, we understand that investing in quality pipe fittings is not just about meeting technical requirements; it’s about safeguarding productivity, safety, and long-term reliability. For industries across the UAE, the choice of fittings can determine whether a project runs smoothly or faces costly setbacks.

The Role of Pipe Fittings in Industrial Systems

Pipes are the arteries of industrial infrastructure, and fittings are the joints that keep them functioning. They allow pipelines to change direction, branch into multiple lines, or adapt to different diameters. Without reliable fittings, even the strongest pipes cannot perform effectively.

In oil & gas facilities, fittings ensure safe transfer of crude oil and refined products. In construction, they connect water supply systems and HVAC networks. In manufacturing plants, fittings regulate the flow of chemicals and cooling fluids. Across these sectors, fittings are indispensable for maintaining operational continuity.

Why Quality Pipe Fittings Are Critical

The importance of quality pipe fittings lies in their ability to withstand harsh conditions while maintaining performance.

- Safety: Poor fittings can lead to leaks, bursts, or contamination, posing risks to workers and facilities.

- Efficiency: High-quality fittings ensure a smooth flow of liquids, gases, or chemicals, reducing energy loss.

- Durability: Industrial projects often operate under high pressure and temperature. Quality fittings resist corrosion and wear, extending system lifespan.

- Compliance: Many industries in the UAE must adhere to strict standards. Using certified fittings ensures compliance with regulations and international benchmarks.

Consequences of Poor-Quality Fittings

Poor-quality pipe fittings may seem like a minor issue at first, but their impact on industrial projects can be severe. Here are some of the most common consequences businesses face:

- Leaks in oil pipelines not only waste valuable resources but can also cause severe environmental damage. Cleanup costs are enormous, and companies face reputational harm alongside financial penalties. A single weak fitting can compromise an entire pipeline system.

- Weak fittings in water systems may allow contaminants to enter the supply, posing risks to public health. This can affect communities, industries, and agriculture that rely on clean water. The long-term impact of contamination often outweighs the immediate repair costs.

- Frequent breakdowns in industrial plants are a common result of poor-quality fittings. Each failure leads to downtime, disrupting production schedules and increasing maintenance expenses. Over time, these interruptions erode efficiency and profitability.

- Hidden costs outweigh savings when businesses choose cheaper fittings. While the upfront price may seem attractive, the expense of replacements, repairs, and lost productivity quickly surpasses initial savings. Quality fittings prove more economical in the long run.

Ultimately, the cost of replacing faulty fittings far outweighs the initial savings from choosing cheaper alternatives. This is why businesses increasingly rely on trusted pipe fittings suppliers in UAE, like Al Kun Steel, who prioritize quality, reliability, and long-term performance.

Key Applications of Quality Pipe Fittings

Quality fittings are used across a wide range of industries:

- Oil & Gas: In this sector, fittings are critical for maintaining secure connections in pipelines that transport crude oil, natural gas, and refined products. A single weak joint can compromise safety and efficiency, so durable fittings are essential to withstand high pressure and harsh environments.

- Construction: Quality fittings ensure reliable performance in water supply systems, HVAC installations, and fire safety networks. They help buildings function smoothly, providing consistent water flow, climate control, and emergency protection, all vital for modern infrastructure projects.

- Manufacturing: Industrial plants depend on durable fittings for chemical transfer, cooling systems, and production lines. These fittings must resist corrosion and wear, as even minor failures can disrupt operations, halt production, and increase maintenance costs.

- Municipal Services: In public water distribution and treatment facilities, long-lasting fittings guarantee uninterrupted service. They help maintain clean water supplies, support sanitation systems, and ensure communities benefit from safe, reliable infrastructure.

These examples highlight how fittings, though small, play a critical role in large-scale operations.

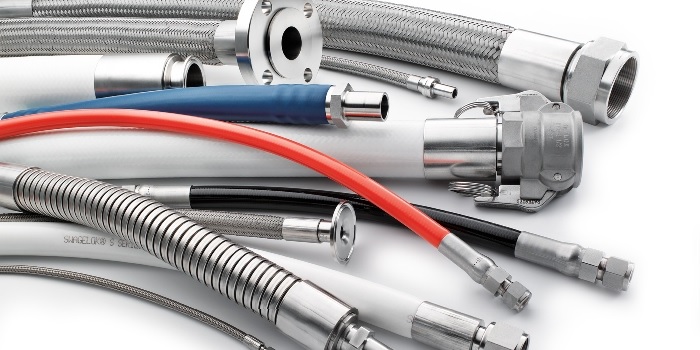

Different Types of Pipe Fittings

There are different types of pipe fittings, each serving a unique purpose:

- Elbows: Used to change the direction of flow in a pipeline, typically at 45° or 90° angles. They help systems adapt to space constraints without disrupting fluid movement.

- Tees: Allow branching into multiple lines, enabling a single pipeline to split into two or more directions. They are essential for distributing flow across complex networks.

- Reducers: Connect pipes of different diameters, ensuring smooth transition of flow between larger and smaller sections. They help maintain pressure balance and efficiency.

- Couplings: Join two pipes securely, providing a strong and leak-proof connection. They are often used for extending pipelines or repairing damaged sections.

- Unions: Enable easy disconnection of pipes for maintenance or replacement. Unlike couplings, they allow quick assembly and dismantling without cutting the pipe.

- Valves: Control the flow of liquids or gases within a system. They can start, stop, or regulate flow, making them vital for safety and operational precision.

Understanding these types helps businesses select the right fitting for each application, ensuring efficiency and safety.

How to Choose the Right Pipe Fittings

Selecting the right fittings requires careful consideration:

- Material: Select from steel, brass, PVC, or other options based on the fluid being transported and the surrounding environment. The right material ensures durability and resistance to corrosion.

- Compatibility: Fittings must match the pipe material and the type of fluid or gas in use. Proper compatibility prevents leaks, contamination, and system inefficiencies.

- Pressure & Temperature Ratings: Always choose fittings that can withstand the operating pressure and temperature of the system. This ensures safety and long-term reliability under demanding conditions.

- Supplier Credibility: Partner with a trusted pipe fittings supplier who provides certified products and technical support. Reliable suppliers guarantee quality and compliance with industry standards.

Al Kun Steel’s Commitment to Quality

As one of the leading pipe fittings suppliers in UAE, Al Kun Steel is committed to delivering products that meet international standards. Our fittings are rigorously tested for durability, performance, and safety, ensuring they serve industries reliably across the region and withstand the pressures of demanding environments.

Whether you need fittings for oil pipelines, construction projects, or municipal water systems, Al Kun Steel provides solutions tailored to your requirements. By prioritizing quality pipe fittings, we help businesses protect their investments, reduce maintenance costs, and achieve long‑term success with fittings that combine reliability, compliance, and performance.

Conclusion

In industrial projects, pipe fittings are far more than simple connectors; they are vital to ensuring safety, efficiency, and reliability. Poor-quality fittings can compromise entire systems, leading to leaks, breakdowns, and costly downtime, while high-quality fittings guarantee smooth operations and compliance with industry standards. Their role may seem small, but their impact on overall performance is significant.

For businesses in the UAE, partnering with a trusted pipe fittings supplier like Al Kun Steel provides access to durable, certified products that stand the test of time. Quality pipe fittings help maintain pressure integrity, reduce wear on equipment, and extend the service life of industrial networks. In this sector, quality is not optional - it is essential.

Related Articles

Stainless Steel Buttweld Fittings For Offshore Shipbuilding And Platform Piping

Read MoreIndustrial Valves, Hoses & Gaskets: Alkun Steel’s Solutions for the Tanks & Pumps Industry

Read MoreCorrosion-Resistant Valves, Flanges & Joints: Alkun Steel’s Petrochemical Solutions

Read MoreWhy Alkun Steel Is A Reliable Supplier Of Essential Products In The Oil Drilling & Rig Industry

Read MoreReliable Industrial Components For Fire Fighting Applications: Alkun Steel’s Trusted Solutions

Read MoreWhy Alkun Steel Is A Reliable Supplier Of Essential Products In The Fabrication Industry

Read MoreIndustrial Valves, Hoses & Gaskets: Alkun Steel’s Solutions For Aviation Maintenance

Read MoreBest Weld Neck, Slip-On, And Blind Flanges For Critical Oil & Gas Connections

Read MoreBest Industrial Fasteners for Heavy Equipment Assembly and Structural Steel Projects

Read More