Stainless Steel Flange Types for High-Pressure Oil & Gas Applications

Choosing the right flange is critical for ensuring safety, reliability, and long-term performance in any industrial piping system. Whether you’re operating within the oil and gas sector, chemical processing, water infrastructure, or general manufacturing, each application demands a specific flange type that can withstand pressure, corrosion, temperature fluctuations, and operational load. In this blog, we aim to simplify the technicalities around the different types of flanges, how they function, and where they are used, especially within the challenging conditions of the UAE and GCC region.

As one of the established SS Flanges suppliers in UAE, we at Alkun Steel understand the confusion buyers face when selecting the right material, design, or pressure class. That’s why this guide covers what you can expect from stainless steel flanges, how each type differs, and why the types of flanges used in the oil and gas industry differ from the rest.

What Are Stainless Steel Flanges?

Stainless steel flanges are forged or cast components used to connect pipes, valves, pumps, and equipment to create a secure and leak-proof piping system. They are designed to withstand high pressure, high temperature, and corrosive environments, making them a preferred choice for sectors such as petrochemicals, oil and gas, desalination, and industrial infrastructure. The strength of stainless steel allows these flanges to maintain structural integrity even when exposed to continuous vibration, thermal stress, or abrasive materials.

At Alkun Steel, our stainless steel flanges are manufactured to global standards and tested for durability, precision, and long service life. Their design allows easy dismantling for cleaning, maintenance, or inspection, which reduces downtime and operational cost. Whether your requirement involves high-pressure lines, sensitive chemical flow, or hazardous media transportation, stainless steel flanges remain one of the most reliable solutions.

Types Of Flanges

Before choosing a specific flange, it’s important to understand that each design serves a unique purpose. Some offer superior strength, some simplify installation, and others are chosen for easier inspection or maintenance. Below is a clear breakdown to help you navigate through the different types of flanges commonly used across industries.

Weld Neck Flange

The weld neck flange is widely used in high-pressure oil and gas applications due to its long tapered neck that reinforces the connection between the pipe and the flange. Before installation, this flange is butt-welded to the pipe, creating a highly durable, stress-resistant joint. This design makes it one of the safest choices for demanding systems that operate under extreme pressure and temperature.

- Long tapered hub for stress distribution

This design ensures that mechanical stress is evenly transferred to the pipe, reducing the chances of cracks or failure during prolonged use. It is ideal for systems handling steam, chemicals, or heavy-duty fluids. - Strong welding connection

The butt-weld attachment provides structural reinforcement, making it suitable for critical pipelines within refineries and petrochemical plants. - Preferred in oil & gas operations

As major weld neck flange suppliers, we deliver flanges that perform safely under extreme conditions typically found in the oil and gas sector.

Threaded Flange

The threaded flange is a preferred choice in environments where welding is not possible or not recommended. It features an internal thread that matches the external thread of a pipe, allowing quick and safe assembly. This makes it ideal for applications where high heat from welding may pose a risk or damage nearby components.

- Internal threading for quick installation

This eliminates the need for welding, making it perfect for sites where fire hazards exist or where equipment cannot be exposed to high temperatures. - Suitable for low-pressure applications

These flanges are commonly found in gas lines, compressed air systems, and explosive zones where welding sparks must be avoided. - Easy removal and reinstallation

The threaded design supports convenient dismantling during routine maintenance.

Blind Flange

The blind flange is used to completely close or seal the end of a pipeline, equipment opening, or pressure vessel. Since it does not have a bore, it is designed to withstand internal pressure while providing secure isolation. This makes blind flanges extremely useful for pressure testing, maintenance shutdowns, and permanent system terminations.

- Complete flow isolation

It is used to shut off pipelines temporarily or permanently, allowing easy inspection or cleaning of the system. - High-pressure resistance

As reliable blind flange suppliers in UAE, our flanges are designed to withstand substantial flow pressure without deformation or leakage. - Ideal for testing pipelines

Industries often use blind flanges to test the long-term durability and pressure capacity of a pipeline section.

Socket Weld Flange

A socket weld flange is engineered for small-diameter, high-pressure lines where a strong and vibration-resistant connection is essential. The pipe is inserted into the recessed area of the flange before being welded, resulting in excellent alignment and improved flow integrity. This design makes socket-weld flanges suitable for piping systems that undergo frequent pressure fluctuations.

- Recessed socket for strong pipe placement

This structure ensures accurate alignment and strong welding, reducing the risk of leakage under pressure. - Suitable for small pipe sizes

They are mostly used in chemical plants, hydraulic systems, and industrial processing lines. - High fatigue resistance

These flanges can handle frequent pressure surges and vibration, increasing their lifespan in heavy-duty applications.

Why Choose Alkun Steel?

As one of the dependable stainless steel flanges dealers in UAE, Alkun Steel stands out for several reasons:

- Commitment to Global Standards

Every flange we supply is manufactured in accordance with international specifications, ensuring reliability and performance under the toughest industrial conditions.

- Wide Range of Flange Types and Materials

From weld neck to threaded and blind flanges, we provide multiple options that cater to the exact needs of oil and gas, manufacturing, and construction sectors.

- Quality Control and Material Traceability

Each flange undergoes stringent testing for durability, corrosion resistance, and dimensional accuracy. We ensure full traceability, from material sourcing to final dispatch.

- Fast Delivery Across the UAE

Our strong supply chain enables us to deliver flanges quickly, helping businesses avoid downtime and complete projects without delays.

- Technical Support and Guidance

Our team assists clients in selecting the right flange type based on pressure rating, media, environment, and installation needs, ensuring safe and long-term performance.

Conclusion

Stainless steel flanges play a crucial role in ensuring the safety, strength, and efficiency of industrial piping systems, especially in sectors like oil and gas, where precision and reliability are non-negotiable. Understanding the different types of flanges, their benefits, and their specific applications helps you make informed decisions that directly impact operational performance. Whether you need a weld neck flange, threaded flange, blind flange, or socket weld flange, choosing high-quality components from a trusted supplier makes all the difference.

At Alkun Steel, we take pride in supplying dependable and industry-tested flanges that meet the diverse needs of the UAE market. With our commitment to quality, fast delivery, and technical support, we continue to be a preferred partner among businesses looking for long-lasting stainless steel flange solutions across the region.

FAQs

1. What are the main types of flanges used in the oil and gas industry?

The oil and gas industry commonly uses weld neck flanges, threaded flanges, blind flanges, and socket weld flanges. These flanges are chosen for their strength, pressure-handling capabilities, and ability to maintain leak-proof performance under extreme temperatures and flow conditions.

2. Why are stainless steel flanges preferred for high-pressure applications?

Stainless steel flanges offer excellent corrosion resistance, high tensile strength, and durability, making them ideal for high-pressure pipelines. Their ability to withstand fluctuating temperatures and abrasive media makes them reliable for oil, gas, and petrochemical environments.

3. What is the difference between a weld neck flange and a threaded flange?

A weld neck flange is butt-welded to the pipe and is suitable for high-pressure systems. A threaded flange, on the other hand, connects through internal threading and is used in low-pressure lines or areas where welding is unsafe or impractical.

4. Where are blind flanges typically used?

Blind flanges are used to seal the end of a pipe or a pressure vessel opening. They are ideal for temporary shutdowns, pressure testing, maintenance inspections, and systems requiring complete flow isolation.

5. Are socket weld flanges suitable for high-pressure lines?

Yes. Socket weld flanges are specifically designed for small-diameter, high-pressure pipelines. Their recessed welding design provides excellent fatigue resistance, making them suitable for hydraulic lines, chemical plants, and industrial process systems.

6. Does Alkun Steel supply stainless steel flanges in the UAE?

Yes. Alkun Steel is one of the dependable SS Flanges suppliers in UAE, offering weld neck, threaded, blind, and socket weld flanges meeting global standards for the oil and gas sector and other industrial applications.

7. What factors should I consider when choosing the right flange type?

Key factors include pressure rating, temperature range, pipe size, installation conditions, corrosion exposure, and the fluid or gas being transported. Alkun Steel provides technical guidance to help clients select the correct flange based on their operational needs.

Related Articles

Stainless Steel Buttweld Fittings For Offshore Shipbuilding And Platform Piping

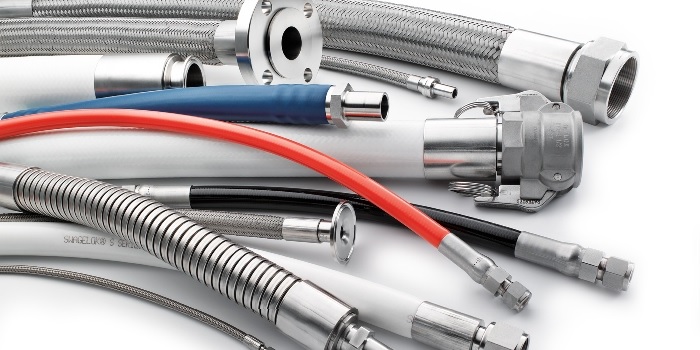

Read MoreIndustrial Valves, Hoses & Gaskets: Alkun Steel’s Solutions for the Tanks & Pumps Industry

Read MoreCorrosion-Resistant Valves, Flanges & Joints: Alkun Steel’s Petrochemical Solutions

Read MoreWhy Alkun Steel Is A Reliable Supplier Of Essential Products In The Oil Drilling & Rig Industry

Read MoreReliable Industrial Components For Fire Fighting Applications: Alkun Steel’s Trusted Solutions

Read MoreWhy Alkun Steel Is A Reliable Supplier Of Essential Products In The Fabrication Industry

Read MoreIndustrial Valves, Hoses & Gaskets: Alkun Steel’s Solutions For Aviation Maintenance

Read MoreBest Weld Neck, Slip-On, And Blind Flanges For Critical Oil & Gas Connections

Read MoreBest Industrial Fasteners for Heavy Equipment Assembly and Structural Steel Projects

Read More