Selecting The Right Metal Nipples For Construction

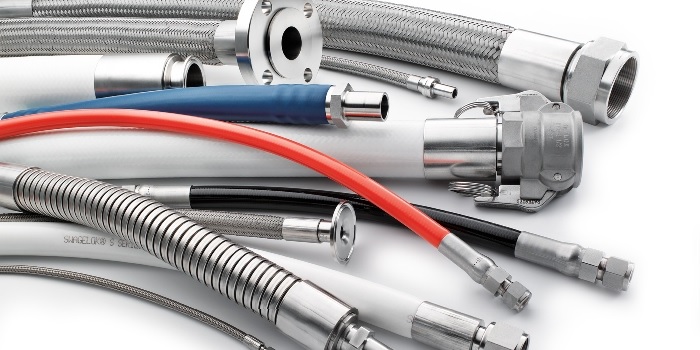

Metal nipples are essential connectors in construction piping systems, playing a crucial role in joining pipes, fittings, and valves. Choosing the right type of metal nipple ensures safety, longevity, and proper flow management in both commercial and industrial projects. From plumbing frameworks to oil and gas pipelines, selecting the correct nipple type is not just about fit—it’s about long-term performance.

At Alkun Steel, we provide premium-quality swage nipples and pipe nipples, manufactured to withstand demanding conditions.

What Are Pipe Nipples?

Pipe nipples are short lengths of pipe, threaded on both ends, that connect two fittings or valves. These are commonly used in applications where the alignment of two components is critical or where an extension is needed.

Key features:

- Made from durable metals like stainless steel or carbon steel

- Available in various lengths, diameters, and thread types

- Ideal for high-pressure environments

You can explore our full range of pipe nipples here.

What Are Swage Nipples?

Swage nipples are designed to connect pipes of different diameters. They come in both concentric and eccentric forms, allowing for smooth transitions in pipe size while maintaining flow integrity.

Key advantages:

- Useful in systems where reducing or enlarging pipe size is required

- Available with beveled, plain, or threaded ends

- Support both vertical and horizontal installations

For more details, browse our collection of swage nipples.

Factors To Consider When Selecting Metal Nipples

1. Material Compatibility

Choose metal nipples made from materials that match or are compatible with the piping system to prevent corrosion and chemical reactions. Stainless steel is preferred for corrosive environments, while carbon steel suits high-pressure industrial systems.

2. Thread Type and Size

Ensure that thread types (NPT, BSP, etc.) on the nipple match the components they’re connecting. Incorrect threading can lead to leakage and system failure.

3. Pressure and Temperature Ratings

Always check the operating pressure and temperature limits. Choosing a nipple that can’t handle the load may compromise safety and efficiency.

4. Application-Specific Needs

Different applications have unique needs. Swage nipples are perfect for diameter transitions, while pipe nipples are used for straight connections. Know your system's design before choosing.

5. Installation Environment

Consider external factors such as moisture, chemicals, and temperature variations that could affect performance over time.

Conclusion

Choosing the right metal nipple—whether it’s a swage or a pipe nipple—is crucial for safe and efficient construction systems. At Alkun Steel, we focus on quality, compliance, and customization to meet your project’s specifications. Always consider your system’s requirements carefully, and consult with professionals if unsure.

FAQ’s

- What is the purpose of a metal nipple in construction?

To connect two pipe fittings, regulate flow, or extend piping in a system. - When should I use a swage nipple instead of a pipe nipple?

Use a swage nipple when connecting pipes of different diameters. A pipe nipple is better for same-size, straight connections. - Can metal nipples be reused?

In most cases, it's best to use new fittings to ensure seal integrity. However, in non-critical systems, undamaged nipples may be reused. - Are Alkun Steel's nipples suitable for high-pressure systems?

Yes. Both our swage and pipe nipples are manufactured to meet high-pressure industrial standards. - What metals are available for Alkun’s pipe nipples?

We offer stainless steel, carbon steel, and other custom alloys based on project requirements. - Do you offer custom sizes for nipples?

Yes, we provide custom machining and size options depending on your project needs. - How do I prevent corrosion in metal nipples?

Select the appropriate metal for your environment (e.g., stainless steel for corrosive settings) and consider protective coatings.

What standards do Alkun’s nipples follow?

Our products adhere to international standards such as ASTM, ASME, and API, ensuring high performance and reliability.

Related Articles

Stainless Steel Buttweld Fittings For Offshore Shipbuilding And Platform Piping

Read MoreIndustrial Valves, Hoses & Gaskets: Alkun Steel’s Solutions for the Tanks & Pumps Industry

Read MoreCorrosion-Resistant Valves, Flanges & Joints: Alkun Steel’s Petrochemical Solutions

Read MoreWhy Alkun Steel Is A Reliable Supplier Of Essential Products In The Oil Drilling & Rig Industry

Read MoreReliable Industrial Components For Fire Fighting Applications: Alkun Steel’s Trusted Solutions

Read MoreWhy Alkun Steel Is A Reliable Supplier Of Essential Products In The Fabrication Industry

Read MoreIndustrial Valves, Hoses & Gaskets: Alkun Steel’s Solutions For Aviation Maintenance

Read MoreBest Weld Neck, Slip-On, And Blind Flanges For Critical Oil & Gas Connections

Read MoreBest Industrial Fasteners for Heavy Equipment Assembly and Structural Steel Projects

Read More