What Would You Choose 304 SS Flangs or 316 SS Flangs

304 or 316 SS flange, which can be a better option, and the answer is ‘it depends

REMINDER:

304 ss flange and 316 ss flange are grades of stainless steel flanges.

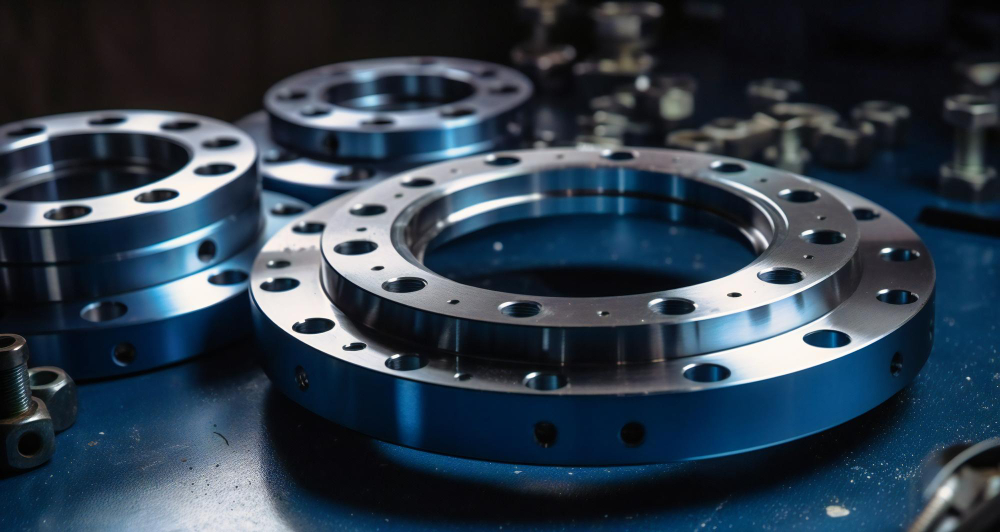

So, SS flanges are equipment that connects segments of pipe systems like pipe or tubing to components such as valves, pumps, or other equipment types. Their use is commonly seen in sectors like petrochemical, chemical, power generation plants, and water-processing units. SS flanges have various types, which include Weld-neck, Slip-on, threaded, etc

And why use SS flanges? Here’s why:

- Heavy Duty: High pressure and extreme temperature applications are where SS flanges are helpful as they are solid and durable

- Safe for use: SS is a remarkably nontoxic and harmless material making it open to a large number of applications

- Immune to decomposition: In unusual environments, extreme temperatures, hazardous chemicals, and heavy pressures, SS is resistant to such conditions and can resist corrosion.

- Low maintenance: The long service life of SS flanges reduces the periodic maintenance and replacement cost reducing the costs overall.

- Easy to clean: SS flanges have majority applications in food, beverages, and pharma sectors, reason? Because they are simple to clean

- Stylish looks: Ss flanges have smooth and glossy eyes, which are suitable for the exposed areas

Now SS flanges are available in various grades like 304/304L, 306/316L, 304 H, 316 H, 321/321 H, 310/310 S, 347/347H, chrome, and Duplex, which vary in their capacity to

resist corrosion.

But the commonly used ones are the 304 and 316, so which one to choose?

A 304 ss flange.

It’s an alloy with 18% chromium and 8% nickel and a strong capacity for resisting corrosion. This alloy mixture makes the SS flange capable of low-moderate temperature or pressure conditions, and they are also more affordable than high-grade flanges for such moderate conditions.

On another side.

316 SS flange also is the same alloy of nickel and chromium with an extra amount of content but with the addition of molybdenum. This gives the flange an increased capacity to resist corrosion caused by chlorine compounds and many industrial solvents, making it a good option for demanding and extreme condition use. And due to the composition changes in 316, the flanges have an enhanced capacity to not corrode in hostile, demanding environments.

But to conclude, it depends on your applications, the environmental components like temperature and pressures, and exposure to chemicals in which the flanges will be used.

With your research, we would also recommend consulting professionals, and Alkulsteel has professional services to help you out. So dail tel: +971-563618951 or email us at Huzefa@alkunsteel.com so that we can help you set up your dreams.

Related Articles

Brass Vs. Aluminium Camlocks: Choosing The Right Material For Your Application

Read MoreExploring the expansion of steel production in GCC and other emerging nations

Read MoreHow Structural Steel Helped The Majestic Architectures Around The World - Part 3

Read MoreHow Structural Steel Helped The Majestic Architectures Around The World - Part 2

Read MoreHow Structural Steel Helped The Majestic Architectures Around The World - Part 1

Read MoreAllowable & Galvanized Iron Pipe Fittings – Trusted Name For All The Pipe Fitting Needs

Read More