Top Features Of Forged Fittings You Should Look For

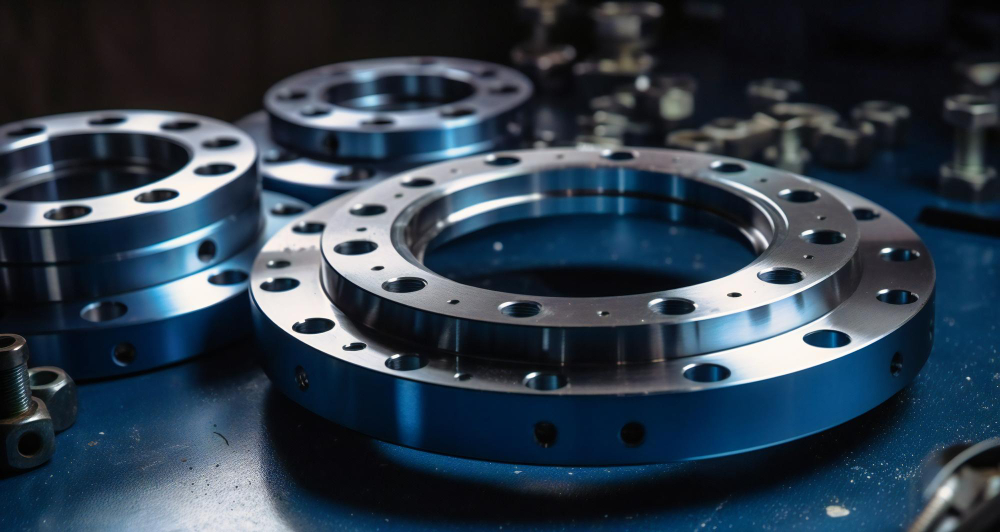

Forged fittings are the ideal kinds of metal fittings that are made with the process of forging, where the metals are shaped in the desired shapes using compressive force. A hammer or die is used for this forging and gives the metals an accurate shape. When you are consulting forged fittings exporter for your requirements, they will always explain the process to you and tell you some of the most amazing features of the fittings. They might have forged the fittings using cold forging or warm forging or hot forging as they desire. But the end product is always accurately forged fittings. The process of creating forged fittings is very simple. The metal piece, usually carbon steel, is placed in between the two of dye pieces which are the upper dye and the lower dye. This is heated to forge the metal in the shape the dye. Sometimes, even a hammer is used to give it accurate and precise design. There are so many features of forged fittings that make them extremely functional. For all those who are planning to buy forged fittings from the forged fittings exporters, here are some of the features that you can take advantage of.

Highly Durable: One of the biggest features that make forged fittings stand out is the fact that they are highly durable. These forged fittings are carved out of forging of the metal over two dyes. These stay intact in their shape for a long time without getting de-shaped.

Accurate Dimensions: The next thing that makes forged fitting so popular instead of the regular fittings is the fact that these fitting are made with dyes and have accurate dimensions. The dyes are created to match the specific requirements of the clients. Once the metal is forged into the hot dye molds, it takes the exact shape. Its dimensional accuracy is what makes it so apt for all industrial uses.

Leak-Proof: The forged fitting also has been known to be leakproof. Whether you are using them in chemical industries or any other industry where there is the use of water or similar liquid component, one thing can be reassured that there would be no leakage. It will seal the surface completely and not allow even a single drop or peck to leak through.

Corrosion Resistant: The next characteristic of forged fittings is that they are totally corrosion-resistant. Owing to the metal that has been used in the making of these fittings, they do not corrode despite being exposed to all kinds of chemicals, water, or other substances. This resistance to getting corroded also gives the, longer life and adds to their extremely nice durability.

Smooth Finish: While many kinds of forged fittings are known to be having a textured finish that is rough, forged fittings have an added advantage that they have a smooth finish. These forged fittings have a very smooth and fine finish that makes these fittings easier to handle.

Related Articles

Brass Vs. Aluminium Camlocks: Choosing The Right Material For Your Application

Read MoreExploring the expansion of steel production in GCC and other emerging nations

Read MoreHow Structural Steel Helped The Majestic Architectures Around The World - Part 3

Read MoreHow Structural Steel Helped The Majestic Architectures Around The World - Part 2

Read MoreHow Structural Steel Helped The Majestic Architectures Around The World - Part 1

Read MoreAllowable & Galvanized Iron Pipe Fittings – Trusted Name For All The Pipe Fitting Needs

Read More