Flanges Suppliers in SUDAN – Alkun Steel

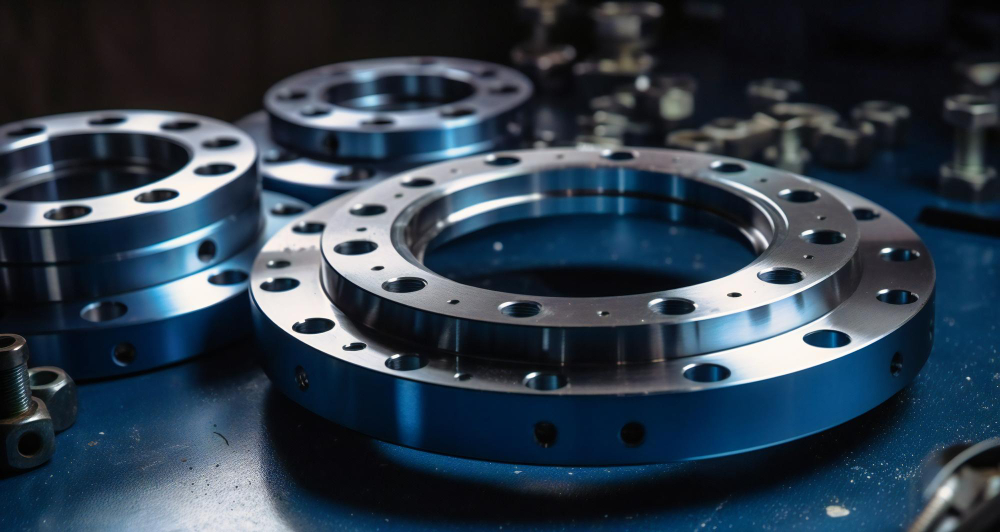

Welcome to the world of piping solutions, where precision engineering meets the flow of innovation. In the dynamic landscape of industrial infrastructure, the role of flanges cannot be overstated. As conduits of connectivity, they form the backbone of seamless operations in diverse sectors ranging from oil and gas to manufacturing and construction. Today, we embark on a journey to explore the array of flanges offered by a trusted name in the industry – Alkun Steel in Sudan. With a commitment to excellence and a legacy of reliability, Alkun Steel stands as a beacon of quality, supplying an extensive range of flanges tailored to meet the unique needs of its clientele. Let's delve into the world of flanges, where Alkun Steel reigns supreme.

Different Types of Flange & Their Uses

Slip-on Flange Supplier in SUDAN

Slips onto the pipe and then welded for a secure connection.

Weld Neck Flange Supplier in SUDAN

This flange has a long tapered hub for welded connections, which is ideal for high-pressure applications.

Blind Flange Supplier in SUDAN

This flange seals the end of a pipe or vessel and is used for temporary blockage or future expansion.

Socket Weld Flange Supplier in SUDAN

Designed for smaller diameter pipes, welded for a tight seal.

Orifice Flange Supplier in SUDAN

Used for flow measurement or restriction in pipelines.

RTJ Flange Supplier in SUDAN

Uses a ring joint gasket for high-pressure applications.

Threaded Flange Supplier in SUDAN

Features threads for easy installation and removal.

Lap Joint Flange Supplier in SUDAN

It allows for easy alignment of bolt holes and is ideal for non-standard connections.

Spectacle Blind Flange Supplier in SUDAN

This flange combines the functionality of a blind flange and a spacer to isolate sections of the piping system.

Grooved Flange Supplier in SUDAN

Uses grooves and gaskets for easy assembly and disassembly.

Square Flange Supplier in SUDAN

Typically used in square tubing or structures.

Marine Flange Supplier in SUDAN

This flange is designed to meet Japanese industrial standards and is suitable for marine applications.

Carbon Steel Flange Supplier in SUDAN

Carbon steel flanges are essential for piping systems to connect pipes, valves, pumps, and other equipment. They are made from carbon steel, a steel alloy primarily composed of iron and carbon, with different elements added to enhance properties like strength, hardness, and durability. Carbon steel flanges are known for their strength, resistance to corrosion, and affordability, making them widely used in various industrial applications.

Several carbon steel flanges are designed for specific purposes and applications. Some of the most common types include:

1. Slip-on Flanges in SUDAN (SO): These flanges have a slightly larger bore diameter than the outside diameter of the pipe. They are slipped over the pipe and then welded at the inner and outer edges, providing a strong and secure connection.

2. Weld Neck Flanges in SUDAN (WN): Weld neck flanges feature a long, tapered hub that provides an ideal pipe connection. They are welded to the pipe and the adjoining pipe, offering excellent strength and stability, particularly in high-pressure and high-temperature applications.

3. Blind Flanges in SUDAN (BL): Blind flanges seal the end of a pipe or vessel. They are typically used in applications where future expansion might be needed or temporarily block off a pipeline.

4. Socket Weld Flanges in SUDAN (SW): Socket weld flanges are designed with smaller-diameter pipes. They are welded directly onto the pipe, creating a smooth bore and a tight seal.

5. Threaded Flanges in SUDAN: These flanges have internal threads that allow them to be screwed onto the pipe. They are commonly used in low-pressure applications and where welding is not feasible.

6. Lap Joint Flanges in SUDAN (LJ): Lap joint flanges are used with stub ends. They allow for easy alignment of bolt holes and are ideal for non-standard connections or systems requiring frequent dismantling.

7. Orifice Flanges in SUDAN: Orifice flanges are specifically designed for flow measurement or restriction applications. They feature a small orifice opening that can be used with an orifice plate to measure flow rates.

8. Ring-Type Joint (RTJ) Flanges in SUDAN: RTJ flanges use a ring joint gasket to create a tight seal in high-pressure and high-temperature applications. They are commonly used in the oil and gas industries.

These are just a few examples of the many carbon steel flanges available, each with unique features and advantages suited to different piping requirements.

|

Carbon Steel Flange Standards |

ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

|

Carbon Steel Flange Pressure Rating ANSI |

Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

Slip-on CS (Carbon Steel) Flange Supplier in SUDAN

|

Standards |

ASTM A105, ASTM A182 |

|

Sizes |

1/2'' to 24'' |

|

Pressure Ratings |

Class 150 to 2500 |

|

Face Type |

RF, RTJ |

Weld Neck CS (Carbon Steel) Flange Supplier in SUDAN

|

Standards |

ASTM A105, ASTM A182 |

|

Sizes |

1/2'' to 24'' |

|

Thickness |

Schedule 10(S) to SCH 160 |

|

Pressure Ratings |

Class 150 to 2500 |

|

Face Type |

RF, RTJ |

Blind CS (Carbon Steel) Flange Supplier in SUDAN

|

Standards |

ASTM A105, ASTM A182 |

|

Sizes |

1/2'' to 24'' |

|

Thickness |

Schedule 10(S) to SCH 160 |

|

Pressure Ratings |

Class 150 to 2500 |

|

Face Type |

RF, RTJ |

Socket Weld CS (Carbon Steel) Flange in SUDAN

|

Standards |

ASTM A105, ASTM A350 LF1/2, ASTM A181 |

|

Sizes |

1/2 inch to 24 inch |

|

Thickness |

Schedule 40 to 160 |

|

Pressure Ratings |

Class 150 to Class 2500 |

|

Face Type |

RF, RTJ |

Orifice CS (Carbon Steel) Flange Supplier in SUDAN

|

Standards |

ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, |

|

Sizes |

1/2″ to 48″ |

|

Pressure Ratings |

Class 150, 300, 600, 900, 1500, 2500 |

|

Face Type |

Flat Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

RTJ (Ring Type Joint) CS (Carbon Steel) Flange Supplier in SUDAN

|

Sizes |

1/2”, 2”, 3”, 4”, 6”, 8”, 10”, 12” to 24” |

|

Pressure Ratings |

Class 150 (lb) up to 24" Class 300 (lb) up to 20" Class 600 (lb) up to 20" Class 900 (lb) up to 16" Class 1500 (lb) up to 10" Class 2500 (lb) up to 8" |

|

Face Type |

RTJ (Ring Type Joint) |

Threaded CS (Carbon Steel) Flange Supplier in SUDAN

|

Standards |

ASTM A105, ASTM A182 |

|

Sizes |

1/2'', 1'', 2'', 3'', 4'' to 24'' |

|

Pressure Ratings |

Class 150 to 2500 |

|

Face Type |

Raised face (RF), Ring type joint (RTJ) |

Lap Joint CS (Carbon Steel) Flange Supplier in SUDAN

|

Standards |

ASTM A105, A350 LF2 |

|

Sizes |

1/2'' to 24'' |

|

Thickness |

SCH 10, SCH 40, SCH 160 |

Spectacle Blind CS (Carbon Steel) Flange Supplier in SUDAN

|

Standards |

ASME B16.48, ASME B16.5, ASME B16.20, ASME B16.47 |

|

Sizes |

1/2" to 96" |

|

Pressure Ratings |

Class 150 to 2500 |

|

Face Type |

flat face, raised face, octagonal, or RTJ |

Grooved CS (Carbon Steel) Flange Supplier in SUDAN

|

Sizes |

1½" to 10" |

|

Coating |

Red Paint, Galvanized Paint |

Square CS (Carbon Steel) Flange Supplier in SUDAN

|

Standards |

ANSI B16.5, ANSI B16.47, ANSI B16.36, ANSI B16.48, BS 4504, EN1092, UNI 2277/2278, DIN, JIS, SABS1123, GOST-12820 |

|

Sizes |

½” to 48″ |

|

Pressure Ratings |

150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

|

Face Type |

Flat Face (FF), Raise Face (RF), Ring Joint (RJT) |

Marine CS (Carbon Steel) Flange supplier in SUDAN

|

Standards |

ASTM A105, A350 LF2 |

|

Sizes |

DN15 – DN1500 |

|

Thickness |

SCH10 – SCH160 |

|

JIS Standard |

5k, 10k, 16k, pn6 |

Stainless Steel Flange Supplier in SUDAN

Stainless steel flanges are made from stainless steel, a corrosion-resistant alloy known for its durability, strength, and resistance to rust and corrosion. They are widely used in various industries, including chemical processing, oil and gas, food processing, pharmaceuticals, and water treatment, where corrosion resistance and hygiene are essential.

Here are the different types of stainless steel flanges:

1. Slip-on Stainless Steel Flange in SUDAN: These flanges have a bore slightly larger than the outer diameter of the pipe. They are slipped over the pipe and then welded on both sides for a secure connection.

2. Weld Neck Stainless Steel Flange in SUDAN: These flanges have a long tapered hub designed to provide an ideal pipe connection. They are welded inside and outside to ensure strength and stability, especially in high-pressure and high-temperature applications.

3. Blind Stainless Steel Flange in SUDAN: These flanges seal the end of a pipe or vessel. They are commonly used in applications where future expansion may be needed or to temporarily block off a pipeline.

4. Socket Weld Stainless Steel Flange in SUDAN: Designed for smaller diameter pipes, these flanges are welded for a tight seal. They feature a recessed area to insert the pipe, providing a smooth flow path.

5. Threaded Stainless Steel Flange in SUDAN: These flanges have threads machined onto their inner bore, allowing them to be screwed onto the pipe for easy installation and removal.

6. Lap Joint Stainless Steel Flange in SUDAN: These flanges allow for easy alignment of bolt holes. They are often used in non-standard connections or where the alignment of the bolt holes is critical.

7. JIS/Marine Stainless Steel Flange in SUDAN: Designed to Japanese Industrial Standards, these flanges are suitable for marine applications. They come in various pressure ratings, such as 5k, 10k, pn6, and 16k, catering to different requirements in aquatic environments.

Each type of stainless steel flange offers specific features and benefits, making them suitable for various applications across different industries.

|

Stainless Steel Flange Standards |

ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

|

Stainless Steel Flange Pressure Rating ANSI |

Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

Slip-on SS (Stainless Steel) Flange Supplier in SUDAN

|

Standards |

ASTM A105, ASTM A182 |

|

Sizes |

1/2'' to 24'' |

|

Pressure Ratings |

Class 150 to 2500 |

|

Face Type |

RF, RTJ |

Weld Neck SS (Stainless Steel) Flange Supplier in SUDAN

|

Standards |

ASTM A105, ASTM A182 |

|

Sizes |

1/2'' to 24'' |

|

Thickness |

Schedule 10(S) to SCH 160 |

|

Pressure Ratings |

Class 150 to 2500 |

|

Face Type |

RF, RTJ |

Blind SS (Stainless Steel) Flange Supplier in SUDAN

|

Standards |

ASTM A105, ASTM A182 |

|

Sizes |

1/2'' to 24'' |

|

Thickness |

Schedule 10(S) to SCH 160 |

|

Pressure Ratings |

Class 150 to 2500 |

|

Face Type |

RF, RTJ |

Socket Weld SS (Stainless Steel) Flange Supplier in SUDAN

|

Standards |

ASTM A182 F304/L, F316/L |

|

Sizes |

1/2 inch to 24 inch |

|

Thickness |

Schedule 40 to 160 |

|

Pressure Ratings |

Class 150 to Class 2500 |

|

Face Type |

RF, RTJ |

Threaded SS (Stainless Steel) Flange Supplier in SUDAN

|

Standards |

ASTM A105, ASTM A182 |

|

Sizes |

1/2'', 1'', 2'', 3'', 4'' to 24'' |

|

Pressure Ratings |

Class 150 to 2500 |

|

Face Type |

Raised face (RF), Ring type joint (RTJ) |

Lap Joint SS (Stainless Steel) Flange Supplier in SUDAN

|

Standards |

A182 F304/F304L/F316/F316L/F321 |

|

Sizes |

1/2'' to 24'' |

|

Thickness |

SCH 10, SCH 40, SCH 160 |

Marine SS (Stainless Steel) Flange supplier in SUDAN

|

Standards |

ASTM A182 F304, F304L, F316, F316L, F321, F347, F310, F44, F51, etc |

|

Sizes |

DN15 – DN1500 |

|

Thickness |

SCH10 – SCH160 |

|

JIS Standard |

5k, 10k, 16k, pn6 |

Conclusion

In the intricate web of industrial infrastructure, the significance of reliable flanges cannot be understated. As we conclude our exploration into the realm of piping solutions, one name shines brightly amidst the fray – Alkun Steel in Sudan. With an unwavering dedication to quality, precision engineering, and customer satisfaction, Alkun Steel is a leading supplier of diverse flange solutions. Whether it's the robust weld neck flanges for high-pressure applications or the versatile slip-on flanges for streamlined installations, Alkun Steel delivers excellence with every product. As industries evolve and challenges emerge, Alkun Steel remains steadfast in its mission to provide innovative, dependable flange solutions that fuel progress and propel industries forward. Trust in Alkun Steel, where every connection is a testament to strength, reliability, and enduring quality.

Related Articles

Brass Vs. Aluminium Camlocks: Choosing The Right Material For Your Application

Read MoreExploring the expansion of steel production in GCC and other emerging nations

Read MoreHow Structural Steel Helped The Majestic Architectures Around The World - Part 3

Read MoreHow Structural Steel Helped The Majestic Architectures Around The World - Part 2

Read MoreHow Structural Steel Helped The Majestic Architectures Around The World - Part 1

Read MoreAllowable & Galvanized Iron Pipe Fittings – Trusted Name For All The Pipe Fitting Needs

Read More