The Ultimate Guide to Industrial Flanges: Everything You Need to Know

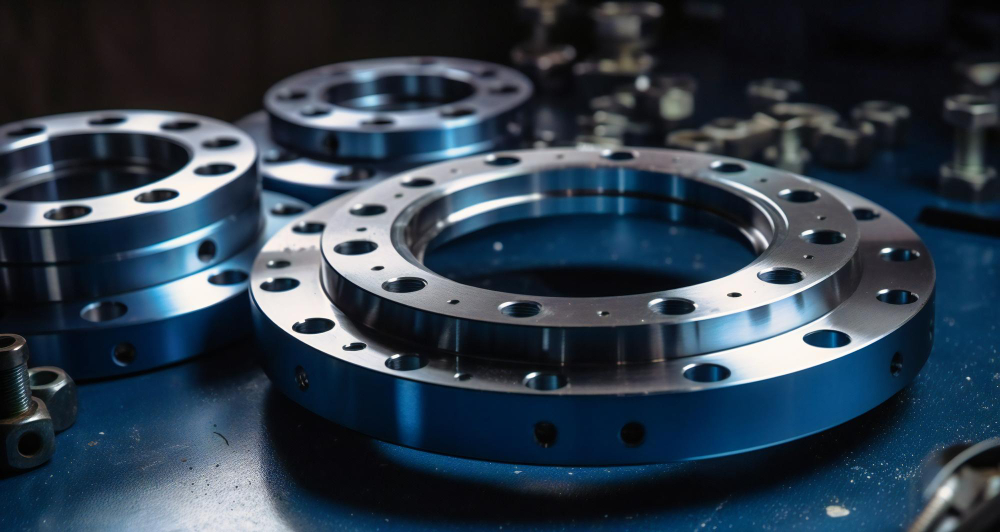

What are flanges?

Modern-day flanges are the second most used technique of connection of the current times. In geek terms, flanges, also known as industrial flanges, can be defined as elements or components that help in joining two or more pipes, valves, and other piping machinery. These act as a catalyst that stimulates easy connection and disconnection between pipes and other equipment. Additionally, as these are popular for their anti-leak and enhanced sealing properties, diverse industrial flanges suppliers across the world recommend using these in multiple industries. Industrial pipe flange fittings are made using the following materials: A. Carbon steel. B. Stainless steel. C. Alloys. . D. Brass. E. Aluminium.

Significant properties of Industrial flanges:

•Durability: Flanges can combat a large number of pressures, depending on their types and design. Made using different materials, these industrial flanges and fittings are the best suited for many industries.

•Anti-leak property: The entire purpose of installing flanges is to obtain secure and leakproof connections. These provide compact sealing, ensuring minimum or no breaching.

•Corrosion resistance: Corrosion and decay are the two prominent of the piping industries. Using industrial flanges made of anti-corrosive materials and alloys like stainless steel and mitigate these issues.

•Easy installation: Unlike many other joining elements, flanges are the least tedious in terms of assembly and disassembly. These ensure easy installation and alignment of pipes, valves and other equipment.

•Standardization: Flanges adhere to industry standards and requirements like ASME B16.5 or DIN to provide regularity and interchangeability. This standardisation makes it simple to acquire, replace, and integrate flanges into various systems.

Common types of industrial flanges and fittings:

Below are some popular flanges that are used in everyday piping and fitting systems. These types and variations might vary as per the availability and accessibility of various industrial flanges suppliers in the UAE.

1. Slip-on flanges: Slip-on flanges feature a flat face and a bore that slides over the pipe. Following that, they are fused into shape. These flanges are beneficial for low-pressure installations and are simple to set up and align.

2. Weld neck flanges: Weld neck flanges are made for high-temperature and high-pressure situations and have a long-tapered neck. They often offer joint strengthening and stress reduction qualities.

3. Threaded Pipe Flanges: The threaded bore on threaded fittings enables them to be screwed onto the pipe. They are utilised in gentle situations in which fusing is neither desired nor practical.

4. Socket Weld Flanges: For a secure connection, socket weld flanges are fillet welded. Smaller pipelines and high-pressure usage can both use these flanges.

5. Blind flanges: Blind flanges are rigid discs that are used for securing the pipe system's dismissal. Typically, they are utilised for plugging off a pipeline portion or to provide a future joining point.

Industrial flanges and their common industrial uses:

A. Oil and gas: Industrial flanges and fittings are frequently used in oil refineries, offshore drilling rigs, pipelines, and petrochemical facilities in the oil and gas industry. Assuring dependable and leak-free conveyance of oil, gas, and other fluids, they are utilised to link pipes, valves, and equipment in these facilities.

B. Construction: Flanges are employed in developing infrastructure and building projects. They are used in HVAC (heating, ventilation, and air conditioning), sewerage, and fire suppression systems to ensure solid connections and effective flow distribution.

C. Industrial processes: Industrial Flanges are used in manufacturing sectors like steel, automobiles, aviation, and food manufacturing. In order to ease the flow of materials and ensure effective manufacturing methods, they are used to link pipes, conveyors, mixing vessels, and other equipment.

D. Water Processing: Flanges are used in desalination facilities, sewage treatment facilities, and water treatment facilities. They assist in tying together the pipes, pumps, valves, and filters in water distribution systems, allowing for the dependable and effective treatment and transportation of water and wastewater.

Now that we are familiar with the fundamentals of industrial pipe flange fittings, here are some essentials to consider while choosing the right flange:

•Size: In order to achieve an accurate fit, sizing plays a crucial role. If you are sceptical about it, it is recommended to consult credible industrial flanges suppliers.

•Classifications: According to ASTM or ASME standards, there are various categories under which all flanges fall. Some of the standard ones are 2500# (and higher for API), 1500#,900#,600#,300#, 150#.

•Thickness: It is simple to calculate the high pressure that a flange can withstand based on how thick it is; in any application, a thicker flange can tolerate higher pressures.

•Pressure class: Understanding the marginal pressure level at which the flange can sustainably and securely operate is made easier by pressure class. There are various pressure levels accessible for each standard, ranging from high pressure to low-pressure tolerance.

According to your needs and applications, put these factors into consideration before choosing the right industrial flanges and fittings.

Related Articles

Brass Vs. Aluminium Camlocks: Choosing The Right Material For Your Application

Read MoreExploring the expansion of steel production in GCC and other emerging nations

Read MoreHow Structural Steel Helped The Majestic Architectures Around The World - Part 3

Read MoreHow Structural Steel Helped The Majestic Architectures Around The World - Part 2

Read MoreHow Structural Steel Helped The Majestic Architectures Around The World - Part 1

Read MoreAllowable & Galvanized Iron Pipe Fittings – Trusted Name For All The Pipe Fitting Needs

Read More