The ultimate guide to understanding Gasket sheets

Synopsis:

The blog below is articulated with the purpose of highlighting the holistic understanding of industrial gasket sheets, their uses, types and properties. Like a definitive guide, this elaborate blog shares insight into all the things a buyer needs to know before buying and using gasket sheets.

What are gasket sheet materials?

Industrial applications, the majority of times, require a joining material that intends to create a tight seal. Gasket sheets, in simpler terms, are those joining requirements that are designed with the motive of providing an impenetrable and leakproof seal. The ultimate function of these is to prevent the leakage of fluids or gases that flow inside the surfaces. Industrial gasket sheet suppliers provide these in the form of flat sheets or rolls that can be shaped and moulded as per the unique application needs.

Some of its primary properties include:

1. Leak-proof Sealing: These are best known for their blocking potency. These are designed in a way that ensures leakproof and secured fluid and gaseous streams.

2. Versatility: Available in different sizes, dimensions and thicknesses, these gasket sheet materials prove to be supple for many environments and industrial applications.

3. Resilience: In order to provide long-lasting function, gasket sheets are frequently resistant to pressure, chemicals, harsh environments, and temperature extremes.

Industrial Uses of Gasket Sheets:

- Automobile Sector: Here, Gasket sheets are used to produce seals between multiple parts, including cylinder heads, valve covers, oil pans, and exhaust manifolds, in motor vehicles and exhaust systems. They provide appropriate engine efficiency by assisting in avoiding any kind of fluid and gas leaks.

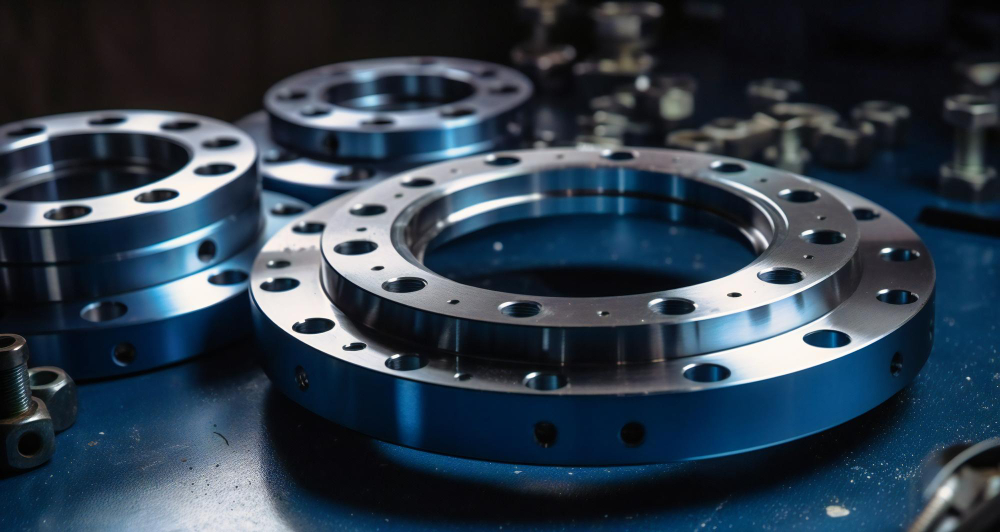

- Chemical Treatment: In chemical plants, intended to protect the system's integrity by resisting corrosive substances and extreme temperatures. These provide tight seal connections between pipes, valves, flanges, and other machinery.

- Oil and Gas sector: They aid in preventing fluid leaks, such as those from oil, gas, and other fluids, ensuring operations are safe and effective.

- Power Generation: Gasket sheets are used in power plants to seal flue gas systems, heat exchangers, boilers, and turbines. By preventing leaks and making sure appropriate sealing is achieved, they aid in maintaining the efficient operation and safety of power generation equipment.

- HVAC (Heating, Ventilation, and Air Conditioning): These gaskets assist systems in sealing ducts, dampers, and access panels. They support ongoing airtightness maintenance and stop energy loss.

Common Types of Gasket sheet material:

1. Rubber gasket sheets: Rubber gasket sheets are sheets of material formed from rubber compounds that are used to seal gaps between two or more surfaces and stop breaches. Due to rubber's superior binding abilities, adaptability, and durability, it is frequently employed in a range of sectors.

2. Asbestos sheets: Asbestos fibres are present in the gasket materials known as asbestos gasket sheets. A naturally occurring substance called asbestos is widely employed in a variety of industries. For their exceptional heat resistance, chemical resistance, and longevity, asbestos gasket sheets are renowned among gasket sheet suppliers.

3. Non-Asbestos sheets: Gasket materials that are specifically made to be free of asbestos fibres include non-asbestos gasket sheets. While offering comparable sealing capabilities to asbestos gasket sheets, they are thought of as safer alternatives. Thereby, these are used in many industries where reliable sealing is required without worrying about health dangers.

4. PTFE or Teflon sheets: Teflon sheets, also known as polytetrafluoroethylene (PTFE) gasket sheets, provide exceptional chemical resistance and low friction characteristics. They are appropriate for uses that call for resistance to corrosive chemicals, high temperatures, and electrical insulation.

5. Metallic sheets: Metal sheets are flat, thin strips of metal that can be carved and moulded to suit a variety of manufacturing and commercial requirements. They are frequently employed in the creation of buildings, equipment production, and equipment creation. Metals such as stainless steel, aluminium, brass, and copper are just a few of the materials.

How to choose the right gasket sheet material?

These are available in many types, sizes, and thicknesses among various gasket sheet suppliers. Therefore, choosing the right one could be a little confusing. Here are some factors that should be considered before buying these gasket sheets. These factors, however, vary from application to application:

a. Temperature: the amount of temperature it will be exposed to and the amount it can withstand.

b. Pressure: Determine the pressure levels and their endurance.

c. What kind of media will it be exposed to? Are the process fluids corrosive or tough?

d. Product standards.

e. Industry standards.

Why buying quality Gasket sheets are a must?

There may be a lot of gasket sheet suppliers, but with Alkun, it is different. We supply quality sheets that enhance the varied features and properties of gasket sheet material. Being the leading gasket sheet supplier in UAE, pro-longed durability and improved functionality are the two things that we promise you.

Related Articles

Brass Vs. Aluminium Camlocks: Choosing The Right Material For Your Application

Read MoreExploring the expansion of steel production in GCC and other emerging nations

Read MoreHow Structural Steel Helped The Majestic Architectures Around The World - Part 3

Read MoreHow Structural Steel Helped The Majestic Architectures Around The World - Part 2

Read MoreHow Structural Steel Helped The Majestic Architectures Around The World - Part 1

Read MoreAllowable & Galvanized Iron Pipe Fittings – Trusted Name For All The Pipe Fitting Needs

Read More