Choosing The Right Gasket Material For Petrochemical Systems

Gaskets may appear to be minor components, but in petrochemical systems, the right gasket can make the difference between safe operation and costly failure. High pressures, extreme temperatures, and aggressive chemicals demand gasket materials that can stand up to harsh conditions. Choosing the right gasket material is crucial to prevent leaks, ensure system reliability, and meet regulatory compliance.

Understanding the Role of Gaskets in Petrochemical Applications

Gaskets serve as sealing materials between two flanges or surfaces, ensuring that fluids or gases do not escape. In petrochemical settings, these seals must withstand:

- High pressure and temperature

- Corrosive chemicals

- Constant mechanical stress

- Vibration and thermal cycling

The wrong material choice could lead to breakdowns, downtime, or even safety hazards. So, understanding your application needs is the first step.

Common Gasket Materials and Their Uses

Each gasket material has specific properties suited for different applications. Here's a breakdown of commonly used materials in petrochemical environments:

1. Rubber Gaskets

Ideal for low to medium pressure applications, rubber gaskets provide excellent flexibility and sealing. They're commonly used for water, mild chemicals, and air.

Explore: Rubber Gaskets

2. Non-Asbestos Gaskets

An eco-friendly and safer alternative to asbestos, these gaskets are made with aramid fibers, fillers, and binders. They're suitable for oils, steam, and chemical services.

Explore: Non-Asbestos Gaskets

3. Asbestos Gaskets

Still used in select legacy applications, asbestos gaskets offer good heat resistance. However, due to health concerns, their use is regulated or phased out in many areas.

Explore: Asbestos Gaskets

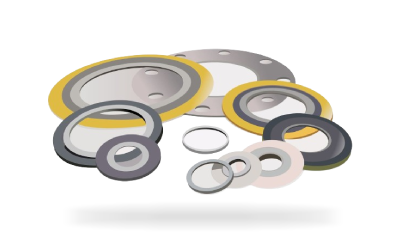

4. Metallic Gaskets

Used in high-pressure and high-temperature applications. These include RTJ (Ring Type Joint) and spiral wound gaskets, which provide excellent resilience and chemical resistance.

Explore:

5. O-Rings

Simple yet effective for dynamic and static sealing, O-rings are used in pumps, valves, and flanges. Material selection varies depending on chemical compatibility.

Explore: O-Rings

Application-Based Gasket Selection

Different petrochemical setups demand specific gasket types. Here’s how application influences your choice:

Full-Face vs Raised-Face Gaskets

- Full-Face Gaskets cover the entire flange surface, ideal for lower pressure.

- Raised-Face Gaskets seal only the raised surface, suitable for higher pressure applications.

Coupling Washers and Specialty Gaskets

Used in specific pipeline and hose systems:

These washers provide effective sealing in fast-connection couplings common in fluid transfer lines.

Factors to Consider When Choosing Gasket Materials

Here are a few key factors engineers and procurement specialists should evaluate:

- Temperature Range – Can the gasket handle the system’s peak operating temperature?

- Pressure Rating – Will the material maintain seal integrity under system pressure?

- Chemical Compatibility – Does the gasket resist degradation from chemicals used?

- Environmental Considerations – Is the gasket safe and compliant with environmental standards?

Conclusion

Choosing the right gasket material for petrochemical systems is a critical decision that directly affects performance, safety, and longevity. Always evaluate your operating conditions, regulatory requirements, and compatibility needs before selecting a gasket. At Alkun Steel, you’ll find a wide range of industrial gaskets tailored for demanding environments—from spiral wound and ring joint gaskets to O-rings, non-asbestos sheets, and coupling washers.

FAQs

1. What gasket material is best for high temperature applications?

Metallic gaskets and spiral wound gaskets are ideal for high temperatures.

2. Are non-asbestos gaskets safe for chemical processing?

Yes, non-asbestos gaskets offer excellent chemical resistance and thermal stability.

3. Can rubber gaskets be used in petrochemical plants?

Only for low-pressure systems with non-aggressive chemicals. Not recommended for hydrocarbons or extreme conditions.

4. What is the difference between full-face and raised-face gaskets?

Full-face covers the entire flange; raised-face gaskets only cover the sealing surface.

5. How do I ensure chemical compatibility?

Check the gasket material's chemical resistance chart or consult your supplier.

6. When should I use spiral wound gaskets?

When you need a strong seal under fluctuating pressure and temperature.

7. Are O-rings reliable for high-pressure petrochemical systems?

Only when made from suitable materials like Viton or PTFE, and within proper design tolerances.

8. Are asbestos gaskets still legal to use?

In some regions, but they are heavily regulated and being phased out due to health risks.