Threaded Valves Supplier in Africa

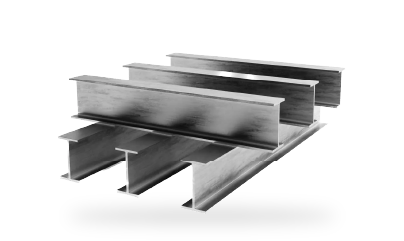

Valves with threaded end connections are appropriate for piping systems with low pressure. These are reasonably priced and guarantee easy and quick assembly for consumers. Once they are assembled, these connections may occasionally be welded around the joint. However, this is not very useful in practice because it may generate issues with the efficient usage of these sorts of valve end connections. As threaded valve suppliers come in two types: Threaded ball valves and threaded gate valves.

A threaded globe valve or ball valve is a specific kind of quarter-turn valve that controls the flow through it using a revolving, perforated, hollow ball. When the ball's hole lines up with the flow, the valve opens; when the handle of the valve rotates the ball 90 degrees, the valve closes. The handle is flat against the flow when it is opened. On the other hand, when it is closed, the handle is perpendicular to the flow. This makes it easier to able to sense the valve's condition. These valves are also known as stop valves, shutdown valves, and isolation valves since they are typically used for basic on/off service.

In contrast to ball valves, the threaded gate valve opens by raising a square or round gate out of the fluid's passage. A sealing surface on gate valves separates the gate and seats. They are frequently used when the minimal restriction is required when a fluid flows in a straight line. A horizontally turning valve and a stem make up a ball valve, on the other hand. Due to the hollow and perforated ball used by ball valves to control the flow, they behave differently than threaded gate valve.

Material Of Construction

- Stainless Steel: Threaded valve suppliers frequently employ stainless steel in the construction of their valves. This is as a result of its great endurance for harsh climatic conditions, leaf-proof nature, and resilience to corrosion.

- Cast Steel: Because of its strong mechanical qualities and resistance to sulfides and corrosion, cast steel is utilized to build threaded gate valves.

- Bronze: Bronze is a common material for the building of threaded globe valves because it is corrosion-resistant and reasonably priced.

- Brass: Brass is quite sturdy and resistant to damage and corrosion, although not being as strong as stainless steel. Because it resists seawater corrosion so well, it is frequently utilized in marine applications.

Industries Used In

- Power industry: In power plants, threaded gate valves are popular for on/off applications.

- Commercial buildings: Every building needs power and water, and a variety of piping systems and valves are employed for this purpose.

- Water industry: Valves are employed in water distribution since it requires low-pressure levels and ambient conditions.

- Wastewater industry: Wastewater treatment facilities employ low-pressure valves to complete their tasks.

- Offshore industry: The pipe systems on offshore oil rigs and production facilities employ a variety of valves.

- Oil and gas production: The valves employed in this sector are made to withstand both extremely high pressures and moderate temperatures.

Showing 1 - 26 of 26 Results