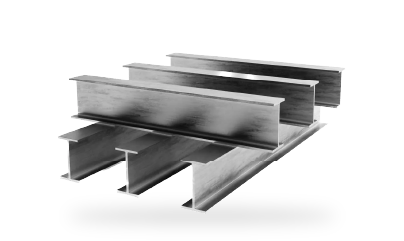

Grooved fittings are mechanical pipe connectors used in a variety of industries to connect pipes of various sizes and materials. They are designed to be quick and easy to install, reducing the amount of time and labor required for pipe installation. Grooved fittings consist of two components - a coupling housing and a gasket. The coupling housing is a metal shell with a grooved end that is designed to fit over the grooved end of the pipe, and the gasket is a flexible material that is placed between the two grooved ends to create a seal.

Grooved fittings have a variety of applications, including plumbing, heating, ventilation, and air conditioning (HVAC), fire protection, and industrial piping systems. They are commonly used in commercial and industrial buildings, hospitals, schools, and other large structures. Grooved fittings are also used in irrigation systems, wastewater treatment plants, and other applications where pipes need to be connected quickly and efficiently.

One of the main advantages of grooved fittings is that they are very versatile. They can be used to connect pipes of different sizes and materials, including steel, copper, plastic, and ductile iron. This makes them an excellent choice for retrofitting older buildings and systems, as well as for new construction projects. Hence get grooved fitting from the best-grooved fittings suppliers in Africa for quality fittings

Another advantage of grooved fittings is that they are very reliable. The grooved design creates a strong, leak-resistant connection that can withstand high pressure and temperature changes. The gasket material is also designed to be long-lasting and resistant to chemicals and other environmental factors.

Grooved fittings are available in a variety of styles and configurations to meet the specific needs of different applications.

Some common types of grooved fittings include:

Couplings: Used to connect two pipes together end-to-end.

Elbows: Used to change the direction of a pipe at a specific angle.

Tees: Used to connect three pipes together at a 90-degree angle.

Reducers: Used to connect pipes of different sizes together.

Crosses: Used to connect four pipes together at a 90-degree angle.

Grooved fittings can be used in a variety of piping systems, including:

Plumbing and HVAC systems: Grooved fittings are commonly used in large commercial and industrial buildings to connect pipes for heating, cooling, and water supply systems.

Fire protection systems: Grooved fittings are used in sprinkler systems and other fire protection systems to connect pipes and ensure reliable water flow.

Industrial piping systems: Grooved fittings are used in a variety of industrial applications, including oil and gas, chemical processing, and mining.

In summary, grooved fittings are a versatile and reliable option for connecting pipes in a variety of industries and applications. They offer a quick and easy installation process, strong and leak-resistant connections, and are available in a variety of styles and configurations to meet the specific needs of different piping systems.

Material Of Construction

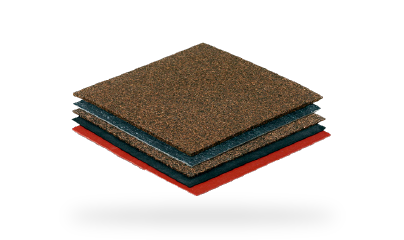

Iron: Al Kun provides grooved pipe fittings and couplings made with ductile cast iron coated with epoxy paint or zinc plated. Iron-grooved fittings are strong and long-lasting. When paired with a good quality gasket, it reduces vibrations and damage to the piping system connection and joints.

Technical Specifications

Thickness

4-8mm

Size

1-inch, 2 inch

Diameter

Up to 25 mm

Industries Used In

- Water Supply Systems: Water supply plants and irrigation systems also used grooved fittings to avoid any leaks in water transport.

- Sewage Treatment Plants: Sewage treatment plants need efficient piping systems that can handle high pressure; this is where grooved fittings come in place. They hold the pining system together, making it more efficient and reliable.

- Chemical And Petrochemical Industries: The safe transport of chemicals is essential in chemical and petrochemical plants. This is why grooved systems are used: their reliability and quick replacement.

- Power Generation: The power generation industry is large. From nuclear to gas and coal, all of these require durable piping systems to create a safe and efficient power transfer. Groove fittings allow one to create a versatile piping system.

- Ship Building: Grooved fittings are used inside ships due to their reliability and quick maintenance. Short repair time is essential to ensure the safety of the people or the ship's cargo.

- Mining: Grooved fittings allow quick maintenance and repairs that reduce downtime in the mining industry. Also, they are popular due to their ability to expand and contract with changing temperature without breaking seams.

- Fire Fighting Systems: Since grooved fittings do not break down easily, unlike welded or soldered seams, they are frequently used in fire protection systems to eliminate the risk of failed or broken seams.